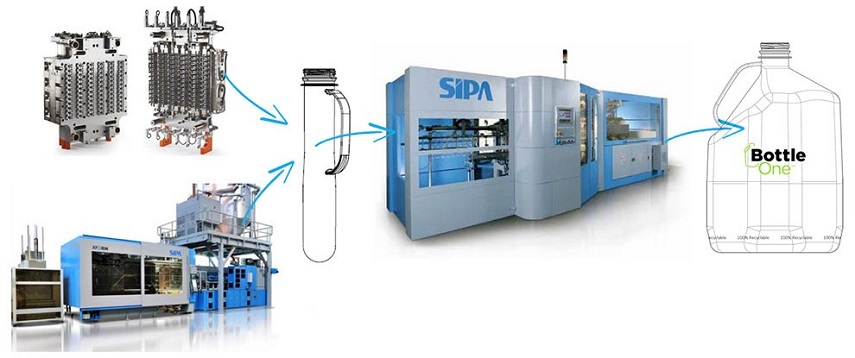

For the development of one-gallon and a half-gallon PET containers with fully integrated handle in replacement of HDPE bottles, BottleOne, a US company based in Atlanta, turned to Sipa, which provided the XForm technology for the injection of special preforms and the SFL linear stretch-blowing system.

Since the handles are an integral part of the preforms, no ancillary equipment is required to apply or attach the handle. The technology incorporated into the preform heating ovens and the bottle moulds is particularly sophisticated. The handle itself has a unique two-point attachment which provides for extra strength and durability.

BottleOne bottles are 100% PET, so that they are very easy to recycle without contaminating the waste stream at the end of their lifecycle. With Xtreme Renew equipment, also by Sipa, and the latest recycling technologies, it is even possible to make the bottles out of 100% post-consumer recycled PET. In terms of processing, PET provides numerous advantages over HDPE. Size-for-size, a handled PET bottle is lighter than an HDPE one thanks to its inherently superior mechanical properties which make it possible to reduce wall thickness significantly. Machine output is far higher, at up to 5,000 bottles per hour per cavity, so less equipment is needed. This helps bring down energy consumption.

The development of PET bottles with fully integrated handle took nearly a decade. It is protected by multiple patents. The initial patent has been approved in eight countries and is now pending in over 20 countries. These bottles have been designed to be ergonomic and offer brand owners new marketing opportunities. They have an accurate aesthetic that is fit for the packaging of various liquid products: milk edible oils, all sorts of juices, fabric softeners, detergents, home care products.