Promoting technological excellence and energy efficiency

The correct process temperature is an essential factor for production, especially in applications where it is necessary to comply with very tight thermal tolerances, such as in plastics processing, and, therefore, even small temperature variations may have a negative impact on process performance. This is the context of the multi-year partnership between Gefran and Frigosystem, where the know-how capitalised in their respective fields is constantly shared with a view to developing tailored solutions in the name of technological excellence and energy efficiency.

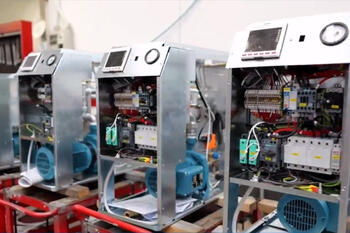

Frigosystem specialises in innovative solutions for refrigeration and thermoregulation in industrial processes. The company operates in various markets, and has gained considerable experience in temperature controlled systems featuring high precision and stability destined for a number of industries ranging from plastics processing to packaging and aerospace, with a turnover of over 13 million euros and a widespread presence in the world thanks to its technical assistance network.

Reliability, scalability, production flexibility and ease of installation: these are the key factors behind a partnership which sees both companies engaged in the joint development of high-tech solutions aimed at meeting every application need, even the most challenging. In this sense, Gefran's added value lies in its ability to combine a wide range of smart controllers and solid-state relays with the tailored software used in the instrumentation.

Of absolute importance is the custom version of the 1350 controller, used for the management of heating cycles in plastic processing. The result of the cooperation of the engineering teams of both companies, this solution has been designed to enhance the controller by integrating crucial process functions for which a dedicated operator interface has been created. In detail, in addition to extremely accurate temperature control, this version allows both the control of various features of the machine, such as the I/O ports for the pumps, and the communication of useful information about temperature adjustments and the status of the actuators.

In addition to the 1350 controller, Frigosystem uses GRS-H solid-state relays with integrated diagnostics, ideal for plastics processing machinery, thanks to the early detection of load breaks or any other faults in the control loop. The users appreciate the many advantages brought by these units: on the one hand, the single-phase solid state relays make it possible to minimise machine downtime and, on the other hand, to limit waste, which always results in higher processing costs. Available with a current intensity range from 15A up to 120 A and voltages up to 600 Vac, the GRS-H relays guarantee easy installation and long-lasting performance.

"Our collaboration began almost twenty years ago and is renewed daily thanks to our common vocation to the development of innovative solutions with a low environmental impact," explained Alessandro Grassi, CEO of Frigosystem (on the left in the photo with Renzo Privitera, Gefran's Sales Manager Italy, sensors and components). "The aspect that we most appreciate about Gefran is the ability to fully satisfy all our specific needs, in a relationship of continuous and profitable exchanges destined to continue successfully over time."