Shutoff nozzles for fast cycles

The product range of Thermoplay (stand D 102, hall 24, at the international exhibition 2015) has been broadened by a new shutoff nozzle, suitable for moulding technical parts, where the injection speed and high pressure require high performance.

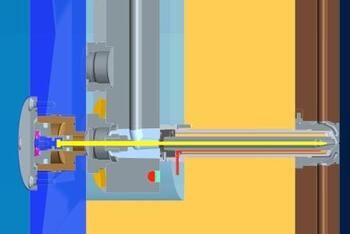

The sealing area between the nozzle head and manifold has been upgraded, in order to compensate the injection pressure increase during fast production cycles. To get an optimal injection rate, the melt channel inside the nozzle has been increased. In addition, the thermal exchange between pin and cavity plate has been improved to achieve a faster cooling of the gate area. Finally, the construction guarantees a mechanical clamping even when the system is not thermally expanded. This represents a safety solution especially when cold start up accidentally happens.

Typical applications of these special solutions are thin wall plastic parts which require high injection speed and fast cooling cycles. The solution is available for the Thermoplay nozzles series FN and DN, diameters 22, 24, 30 and 32 mm. To improve the benefit of this solution a conformal cooling bushing is also recommended by the Thermoplay technicians.

The sealing area between the nozzle head and manifold has been upgraded, in order to compensate the injection pressure increase during fast production cycles. To get an optimal injection rate, the melt channel inside the nozzle has been increased. In addition, the thermal exchange between pin and cavity plate has been improved to achieve a faster cooling of the gate area. Finally, the construction guarantees a mechanical clamping even when the system is not thermally expanded. This represents a safety solution especially when cold start up accidentally happens.

Typical applications of these special solutions are thin wall plastic parts which require high injection speed and fast cooling cycles. The solution is available for the Thermoplay nozzles series FN and DN, diameters 22, 24, 30 and 32 mm. To improve the benefit of this solution a conformal cooling bushing is also recommended by the Thermoplay technicians.