Saving money, while improving process and material quality

Steep quality requirements especially in the high-end film market require 100% defect detection and monitoring of material quality during production. Only comprehensive and reliable material qualification returns optimum material quality and reduces production costs, as inferior material can be eliminated from further processing and delivery to the customer. This saves time and material costs for expensive coatings.

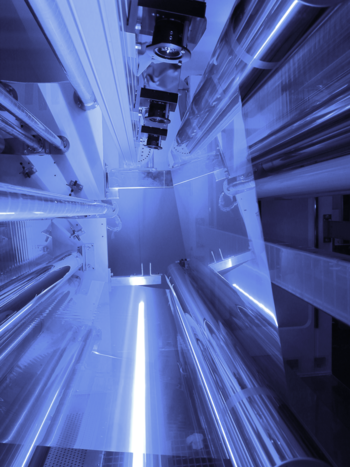

Combining EasyInspect, Dr. Schenk’s multi-channel inspection system for local defect detection, with Dr. Schenk’s EasyMeasure enables highly sensitive optical quality inspection for the complete width of the material. Exactly what film manufacturers are seeking: an easy-to-integrate, reliable and adjustable automatic optic inspection solution providing outstanding detection and classification of defects, large-area monitoring of material properties, such as coating homogeneity, optical density, haze, web thickness or roughness is provided simultaneously.

Comprehensive defect analysis is achieved through the simultaneous use of multiple optical channels (MIDA). This improves defect detectability and increases classification accuracy – and requires significantly lower investment and less space in the production line. MIDA is used for monitoring material quality, for example during the production of: packaging film (flexible, breathable or rigid), metallized film (e.g. barrier films), adhesive film / PSA coating, window film, Li-battery separator / fuel cell, battery electrode.

These solutions and others by Dr. Schenk will be exhibited at stand C02, in pavilion 15, at Plast 2015.

Combining EasyInspect, Dr. Schenk’s multi-channel inspection system for local defect detection, with Dr. Schenk’s EasyMeasure enables highly sensitive optical quality inspection for the complete width of the material. Exactly what film manufacturers are seeking: an easy-to-integrate, reliable and adjustable automatic optic inspection solution providing outstanding detection and classification of defects, large-area monitoring of material properties, such as coating homogeneity, optical density, haze, web thickness or roughness is provided simultaneously.

Comprehensive defect analysis is achieved through the simultaneous use of multiple optical channels (MIDA). This improves defect detectability and increases classification accuracy – and requires significantly lower investment and less space in the production line. MIDA is used for monitoring material quality, for example during the production of: packaging film (flexible, breathable or rigid), metallized film (e.g. barrier films), adhesive film / PSA coating, window film, Li-battery separator / fuel cell, battery electrode.

These solutions and others by Dr. Schenk will be exhibited at stand C02, in pavilion 15, at Plast 2015.