Industry 4.0: certificate of conformity for Exact pelletizers

The certificate of conformity according to the "Industry 4.0-Ready" requirements has been issued by Amaplast (the Italian Plastics and Rubber Processing Machinery and Moulds Manufacturers’ Association) to Exact, a member company based in Zingonia (Bergamo, Italy).

Amaplast's technical department carried out an analysis of the technical features of three pelletizers manufactured by Exact, certifying that they comply with the provisions set out in Annex A to the Italian Law No. 232 of 11 December 2016 and are therefore eligible for tax credit under Italy’s "Transition Plan 4.0", which this year has been increased to 50% of the value of the purchased goods. This is an important way of communicating to the market the possibility of taking advantage of the Industry 4.0 tax credit, provided, of course, that the buyer fulfills his specific requirements (interconnection of the machine to the company information system, etc.).

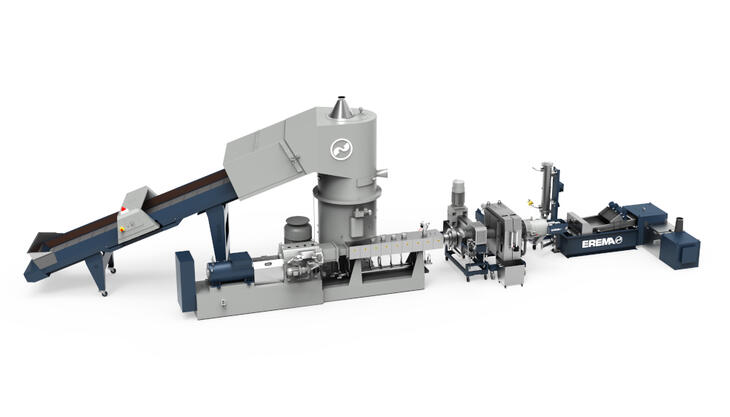

The Evolution 10, Cyklop 20 and Cyklop 30 pelletizers (see the above photo) by Exact have been declared functional to the technological and digital transformation of enterprises according to the Industry 4.0 requirements, i.e. machinery whose operation is controlled by computerized systems or managed through appropriate sensors and drives. Conformity audits are also being completed for other machines built by Exact: the E60 (photo below) and E120 hot pelletizers and the R6 Jumbo and Gold cold pelletizers for thermoplastic film recycling.

The assessment was carried out by Amaplast experts with the analysis of the technical and design documentation of the machinery, an interview with the technical representatives of Exact and its suppliers and a direct analysis of the equipment, with various inspections at the company’s premises. The conformity report describes the technical features of the machines, illustrates their control systems and interconnection to the computer and logistic systems of the factory, also taking into account a number of elements:

The assessment was carried out by Amaplast experts with the analysis of the technical and design documentation of the machinery, an interview with the technical representatives of Exact and its suppliers and a direct analysis of the equipment, with various inspections at the company’s premises. The conformity report describes the technical features of the machines, illustrates their control systems and interconnection to the computer and logistic systems of the factory, also taking into account a number of elements:

- effective man-machine interface;

- compliance with the latest safety criteria;

- preparation for remote maintenance/diagnosis/control systems;

- possibility of continuous monitoring of process conditions and parameters;

- existence of a cyberphysical system.

Amaplast's technical department assists member companies with the provision of further details on the methods and costs necessary for conducting technical analyses and issuing the certificate of conformity. This independent certificate - involving figures like Amaplast engineers, who know the machines and their 4.0 features better than any other in the plastics industry - can concretely support sales on the Italian market, which moreover is showing important signs of recovery.

In fact, according to the survey carried out by Centro Studi Mecs-Amaplast among the association’s members, sales increased by an average of 16% and orders by 64% in the first quarter of 2021 compared to the same period of 2020 - probably thanks also to the investment incentives of the "Transition Plan 4.0".